About us :

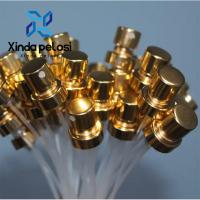

Xinda Pelosi Co., Ltd. was founded in 2016. It is specialized in

the production of all kinds of plastic sprayers.

We are located in Guangzhou City, Guangdong Province,

adjacent to Guangzhou and Shenzhen Airport .

It is an only two-hour drive from our company to Baiyun Airport,

which makes the transportation from or to

even more convenient. Since it is right next to China Plastic City and

China Light Industry Mold City as well,

the unique regional advantages make our company a professional manufacturer of

plastic products.

Our company, covering a land area of 12,000 square meters and a

factory area of 20,000 square meters,

has now become a scientific and technological enterprise

specialized in the production of plastic sprayers

and cosmetic packaging with in-house R&D department,

manufacturing factory and marketing team.

It has been cooperating with many international famous brands in

the industry as well.

Advanced professional technology, superior quality, efficient

marketing services together help our cpmpany

grow and develop continuously.

After years of continuous development, our company has received

various international or domestic quality

system certification such as SGS, TUV, ROHS, ISO9001:2008. The

company has passed the BV Social

Accountability Audit, ITS Quality System Audit and C-TPAT Audit as

well.It has also been following 7s for daily

practical use and strictly control the product quality under IQC,

IPQC, QC, CFQC, QA, OQC flows for testing

and managing the supply chain.

Developing competitive products, building a brand, assuring quality

and continuation is our philosophy.

Your satisfaction is our target. Join us for mutual benefit and

development.

At present, our company is increasing the investment to improve the

management, control quality and

encourage innovation. It is striving to become the industry leader

of sprayer exporting enterprises in China